Typical applications

| Food & Beverage |

| Tomato paste (concentrate), double concentrated tomato paste, tomato puree, tomato pulp, fruit and vegetable concentrate, fruit pulp or base, sauce concentrate, glucose syrup, maltose syrup, corn syrup, high-fructose corn syrup (HFCS) or glucose-fructose syrup (GFS), oat syrup, caramel, peanut butter, almond paste, mayonnaise, nougat paste, chocolate, fudge, cream, beverage base. |

| Cosmetics & Pharma |

| Cosmetic and pharma vaseline, ointment, cream & lotion, semi-solid wax/paraffin, glycerine, oil, lip gloss, mascara, facial cleanser, facial mask. |

| Industry |

| Grease, including heavy duty Lithium-based NLGI class 3 grease, ink, paint, resin, coating and sealing compounds. |

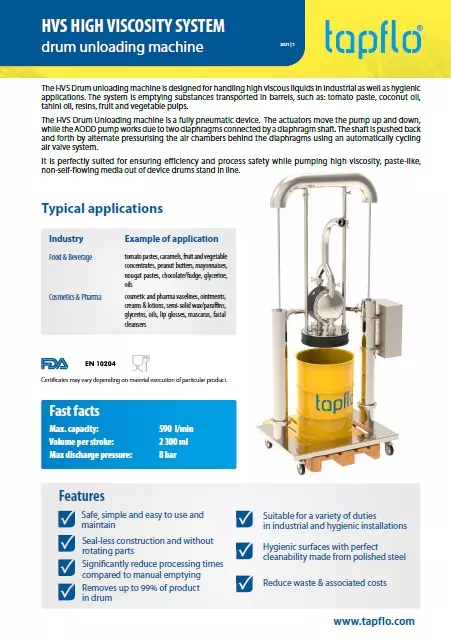

Unloading drums filled with highly viscous liquids has never been easier. Our High Viscosity System (HVS) is designed to simplify this task, offering automated efficiency and exceptional product-saving capabilities. With HVS, you'll experience a smooth unloading process, allowing you to focus on other critical tasks while achieving up to a 99% product removal rate. Say hello to effortless drum unloading with HVS.

Our drum unloading system is equipped with a hygienic double diaphragm pump featuring lifting and lowering capabilities, designed for the efficient unloading of 200-liter drums. Notably mobile, this system offers the convenience of unloading a drum containing double-concentrated tomato paste in under two minutes, showcasing its remarkable speed and efficiency in action.

KEY FEATURES

- Quick unloading of the drums: up to 400 liters per minute, depending on the liquid properties and discharge pressure.

- 99% product extraction: product savings thanks to the applied scraping lid.

- High process safety and time-saving benefits: brought by the control system.